Salsa

Miscellaneous pictures from Ross Shafer. Posted the fronts and back of each set but they occasionally got shuffled out of order. Isn't too tough to figure them out though.

1976

Ross bought the Proteus frame building kit and built his first road bike in three months. When he would show up on the bike, people began to ask about it. Ross agreed to build several frames in his basement and decided that it might be a possible career path. Often times, the best way to learn a new craft is to find a job in a production environment so Ross went looking for an opportunity. There was a chance to go to Chicago and work in the Paramount production facility but the climate change was going to be too much.

1978

Since the frame building community was almost non-existent in the US, Europe was the next option. At this point, Ross had built about 60 frames (under the Red Bush name) and had recently married. Since Ross had never been overseas, England was quite a change. After being there for three days, it became apparent that England was not a viable option. In those three days, the bike that Ross brought with him had been looked over by various bike industry people and declared better than the current production bikes. Since there was nothing left to learn, it was time to head home. Ross stayed on for another month as shop foreman to help prepare for the upcoming Milan bike show.

1979

Ross is now back in the US and looking for work. Still building custom frames while doing some carpentry and working at the Bike Trip. There wasn't enough custom business to work as a full time frame builder so Ross lined up a job at a frame building factory in Los Angeles. When he showed up for the job he was told that they couldn't use him for a couple of weeks so he checked in at Santana to see what they were up to. He was offered a job in the frame building department to build lug-less tandems (after having built one lug less tandem and one lug-less road bike). He accepted the job after learning the details about his previous job offer. That frame shop had a bad reputation for not following up on promised work.

1980

Put in a full year building at Santana and got very proficient at lug-less building and even began to prefer it to lugged frames. Working 8 hours a day at Santana and then going home to build the custom frames was starting to get old.

1981

Ross built one lugged mountain bike under the Red Bush name. It used Hetchins style fancy hand cut lugs and 650b wheels.

1982

A couple of friends start pressuring Ross to build them a couple of mountain bikes. Finally he relents, and builds " the only five mountain bikes that I will ever build". While building them up, Ross decide to do one for himself to see what all the noise was about. He became hooked and switched to mountain biking. Ross built a tandem bike for Brian Bayliss.

Switched the name to Salsa Cycles for a more "commercial" name. The name came from the love of Salsa. Ross often showed up at work with a bag of chips and a jar of picante Salsa. Other names that were considered were Deux Roue (French for two wheels), Psyclls and Salza. The Salsa name worked especially well in conjunction with the pepper logo. Ross took one of the mountain bike frames and showed it around some shops. With only a few builders making frames (Ritchey, Mountain Goat and Mantis) there was a huge wait to get a frame. Within a week, there were 16 frame orders for Salsa which was a big change from the usual two or three bike backlog. With the increased level of orders, Santana was left behind but there production levels fell soon afterwards so they wanted Ross back. He agreed to come back for 5 months as long as he could use the facilities to produce his own bikes as well. The money earned from Santana was used to buy tools and equipment for Salsa. At one point, the waiting list was up to 80 frames.

1983

Ross visits Scot Nicol (Ibis) and falls in love with the Petaluma area. He moves from Santa Cruz and starts Salsa a la carte to go with Salsa custom frames. This is when stem production began by building a custom stem with each frame. There was very little choice in the way of stems back then. Salsa began production of stem in three different sizes.

1984

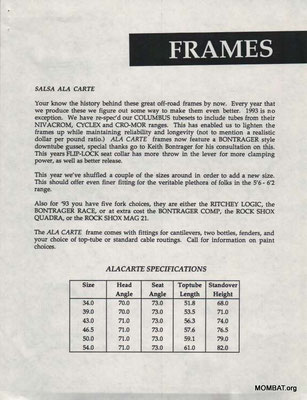

Begin production of the Salsa Alacarte frames in late 1984.

1985

75-100 Alacarte frames were built in 1985 and were pretty much all sold before the tubing arrived. Since stem production was really taking off by this time, this was the only batch of production frames. Custom frames continued to be available.

1986 Started selling in Europe.

1987 May Ross Shafer interview:

July 1987 Bike review:

1988

Products for 1988 include Moto an Pro Moto (with cable roller) stems, TIG welded by hand, 4 stock sizes. Custom stems are also available to order and can be fillet brazed or TIG welded. Moto bars are USA True Temper 4130 Cro-Moly, flat with 11 degree bend, 321 grams, 1.2mm to .9mm taper butted. Also available are t-shirts and portage straps. Frames are available in road or mountain (Alacarte, TIG welded). Each frame is custom made for each customer and will be fillet brazed using quality butted tubing. frames retail for about $1,000. Salsa sponsors an all-woman mountain bike race team led by Martha Kennedy. Salsa provided the custom stems used by the 1988 US Olympic Team Time Trial team. Marty Nothstein won most of his world sprint championships on Salsa custom stems. Quote from Marty "I have GT make my bikes so that they fit me with my Salsa stems"

1988 Salsa catalogs:

August 1988 Bicycle Guide Upgrades article:

1989 Salsa catalog:

1990 Catalog and dealer letter:

1991

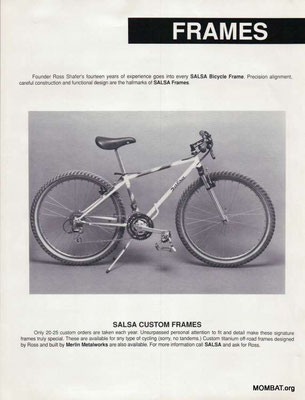

Ross is inducted into the Mountain Bike Hall of Fame. The Alacarte frame now uses Columbus tubing and comes with the Bontrager composite fork and a Pro Moto stem. Salsa Custom frames are available at the rate of about 20-25 per year. "Unsurpassed personal attention to fit and detail make these frames truly special". Ross designed custom titanium frames are available through Merlin Metalworks as well. Salsa stems are available in many different models and options. The standard stem is still the Off-Road stem (Pro Moto with roller and Moto w/o roller_. The new Competition stem shaves about 55g from the standard stem and is recommended for riders under 185 pounds. There are also available in road, track (Sprint) and custom models. Salsa/Merlin titanium handlebars are offered in 5 or 11 degree bends with a 22" width. They are straight gauge, 3-2.5 titanium and weigh in at 184 grams without shims. Salsa wear included caps, bottles, pins, t shirts and Helmet Panties (Lycra and Lace helmet covers) all adorned with the Pepperman or classic Pepper logos. The October 1991 Bicycle Guide magazine features a test of the Alacarte frame and had a few interesting bits of information. They list the output of frames at under 100 per year but projects the output for 1991 at 500. Frame weight was listed at 5 pounds 6.25 ounces in a 49 cm size. Retail price was $900 including the Bontrager fork and Salsa stem. Two future projects are listed in the article. The first is an aluminum handlebar in conjunction with 3ttt and the second is a lightweight aluminum quick release seat collar in conjunction with Northern California neighbor DKG. The April 1991 Bicycle Guide magazine has a one page interview with Ross. Couple of interesting points from the article: there are 55-60 "stock" stems that are kept in stock, stem production is listed as up to 7,000 per year, the factory is located in the basement of a Mexican restaurant, there are 7 employees.

1991 Salsa catalog:

Bicycle Guide interview from April 1991:

October 1991 a la Carte review from Bicycle Guide magazine:

1992 May quick release ad:

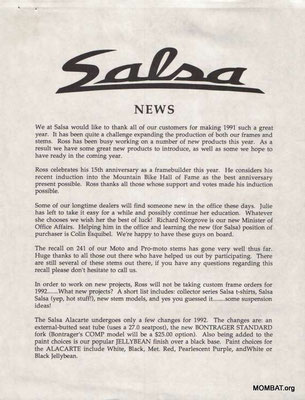

From an early 1992 Salsa Newsletter. Listed is a recall of 241 Moto and Pro-Moto stems. No custom frame orders will be taken for 1992. New projects include: collector t shirts, Salsa new stem models and some suspension ideas. Changes to the Alacarte frame include: external butted seat tube (uses 27.0 seat post), Bontrager standard fork (Comp to be a $25 option) and paint colors will be white, black, metallic red, pearl white, white jelly bean or the new black jelly bean.

New products for 1992: Salsa Pro-Moto handlebars, heat treated 7075 aluminum, produced in Italy by 3ttt, 23" width, 159g, black anodized with laser etched logos. Salsa Flip-Offs, hub quick release with the lever from the Flip-Lock seat collar, conventional quick release motion (no extra twisting needed), stainless steel at 102g and titanium at 86g. Salsa Mangos de Amor, dual position bar ends, clamp on designs, Cro-moly, made in Taiwan. Salsa Ti bolt option for Salsa stems, made by SRP, saves 24g. new Coffee Mugs!!!

1992 Salsa catalog:

April 1992 bar ends and quick releases:

1993

Ross made bikes for Peter Gabriel and his band members David Rhodes (guitar) & Tony Levin (Bass, also of King Crimson). This worked out nicely since Ross had been a fan of Peter Gabriel ever since Peter's work with the band Genesis.

1993 Salsa catalog:

January 1993 Bicycle Guide road bike review:

1993 Caramba crank with Magic Motorcycle and Ross Shafter involvement:

1994 Salsa catalog:

1995

Salsa is listed as having 14 employees and is expected do over one million dollars in sales for 1995. There are 81 different stem models available and sales range between 7,000 and 10,000 per year. The Salsa Caliente Clothing line is with partner Jed Clark. The crank project is listed in 1995 and eventually becomes Caramba, although without Ross. Max (son of Ross) is now 9 years old and is into BMX so the BMX market gets a closer look.

1995 Salsa catalog:

1996

From the 1996 Salsa Catalog: El Kaboing: Cool name, eh? Something from Ross' cartoon days. Again we're sticking with a proven and reliable design. Horst Leitner's McPherson strut design is a proven performer. The CHUMBA WUMBA rear-end we use offers very rigid construction and large diameter, adjustable, self lubricating bushings throughout to ensure as many maintenance-free miles as possible. The stock shock is the Risse Genesis, but the Elroy adjustable unit is also available. With the El Kaboing comes the Rock Shox of your choice as well as a Salsa stem. Light, simple...what are you waiting for? (Note: rear brake must be side activated).

3 frame sizes were: 42, 47, 52

71 degree head angles

73 degree seat angles

Top tube lengths (respectively) 56, 58, 60

Chain stay lengths 42

BB Height 31.5

Standover height (respectively) 76.5, 80, 83

The 1996 catalog also had the Salsa Viajero travel bike frame with S&S couplers.

1996 Salsa catalog:

1997 The Salsa name is sold to a parts distributor, Quality Bikes Parts (QBP). Ross stays on as a designer and consultant.

From the Mountain Bike Hall of Fame:

Ross Shafer

Induction Year: 1991

Ross Shafer built his first road frame in Paradise, California in 1976, and continued to build them under the Red Bush banner between carpentry and bike shop jobs. He finally started building frames full-time when he got a job as head frame builder at Santana Cycles. During that time, he built his first off-road bike (1981) using 650 B wheels.

After a year at Santana, Shafer turned his frame building skills to mountain bikes. Subsequently, Salsa Cycles was born with six custom built bikes utilizing personalized seat angles and the 71-degree head angle Shafer still uses today. His experience with riding road bikes in the dirt convinced him that a mountain bikes ideal geometry lay somewhere between the steepness of modern road bikes and the slack angles predominant on the mountain bikes of the day.

To further enhance the proper fitting of the frames, he started making custom stems in 1982. Salsa Stems emerged in 1984 as Shafer entered the market of quality cro-moly stems and production frames. Later that year he also introduced the roller cable guide.

He produced 100 Ala Carte production frames before stopping to concentrate on manufacturing stems and producing custom frames. The mass-produced frames reappeared in 1987, due to popular demand.

He designed one of the earliest butted cro-moly handlebars in 1987, which was then made by Tru Temper, and the next year a lighter bulged version was introduced.

This was also the year he began sponsoring the first all-women mountain bike racing team and became an official supplier of stems to the U.S. Olympic team time trial squad.

Although he now is charged more and more with managerial duties and less with custom frame building, Shafer continues to develop new products, such as TIG-welded road stems and the Flip-loc quick release system. July 1991